Smart Silo Level Monitoring Solutions

Silo Monitoring Logistics

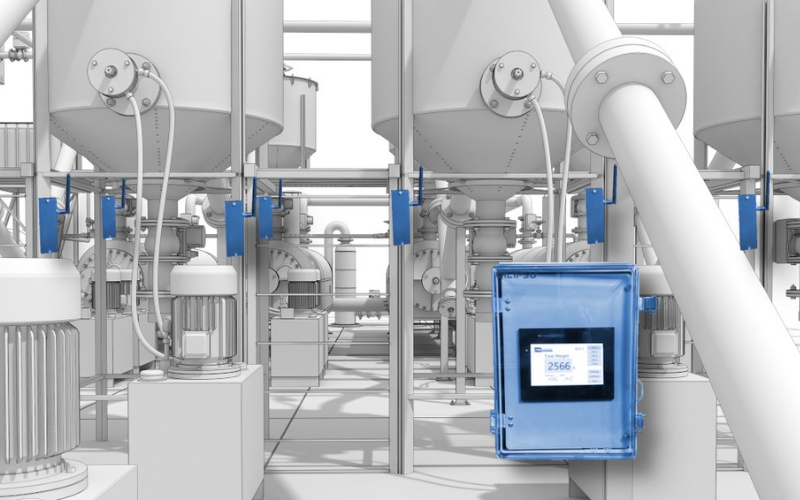

Infotech’s IoT-based Silo Monitoring Logistics system is designed to optimize the management of silos by leveraging cutting-edge sensors and software. These silo monitoring systems provide real-time data on silo levels, silo temperature monitoring, and overall conditions, enabling businesses to enhance efficiency, improve safety, and boost profitability.

Key Benefits of Silo Monitoring

- Accurate Silo Level Monitoring: Real-time tracking of silo levels ensures optimal inventory management, preventing overfilling and understocking.

- Enhanced Safety: Silo temperature monitoring and other inventory sensors help detect and address potential hazards before they escalate.

- Informed Decision-Making: With detailed data from silo monitoring systems, businesses can make better decisions that improve operations and profitability.

How IoT-Based Silo Monitoring Works

Infotech’s system uses inventory sensors and advanced software to monitor silo levels and conditions in real-time. This IoT-enabled approach allows for seamless integration with your existing logistics infrastructure, ensuring that you always have up-to-date information on your silo operations. Additionally, it provides predictive analytics to anticipate potential issues before they arise. By automating routine checks, it reduces manual labor and minimizes the risk of human error.

Achieve Efficiency and Safety

By investing in Infotech’s silo monitoring systems, companies can achieve greater operational efficiency, reduce risks, and improve overall performance. Whether you need to monitor silo temperature or track inventory levels, Infotech’s solutions provide the data and insights necessary for success.

FAQ

A silo monitoring system is a technology solution that tracks the level, temperature, and condition of materials stored in silos, ensuring efficient inventory management and preventing material loss or damage.

A silo system uses sensors to measure the levels of stored materials, temperature, and humidity, providing real-time data on storage conditions and ensuring proper maintenance of materials inside the silo.

IoT-based silo monitoring provides real-time data on material levels, allowing for precise inventory tracking, automated reordering, and reducing the chances of stock shortages or overstocking.

Silo temperature monitoring can detect hazards such as overheating, moisture buildup, and spoilage, which can lead to material damage, fires, contamination, or other significant safety risks.

IoT-enabled silo monitoring improves profitability by optimizing inventory levels, reducing material waste, minimizing downtime, and improving operational efficiency through automated data collection.

Silo monitoring is essential in Qatar due to its hot climate, where temperature and humidity control are crucial to prevent spoilage, ensure quality, and optimize material management in industries like agriculture and construction.

IoT improves silo monitoring by providing real-time data on material levels and conditions, allowing for predictive maintenance, timely refills, and reducing manual checks, leading to greater efficiency.

Infotech’s silo monitoring solutions offer advanced IoT technology that ensures real-time data, enhanced efficiency, and improved safety for industries in Qatar, tailored to meet local environmental challenges.

Real-time data provides instant insights into material levels, temperatures, and conditions, enabling timely actions to prevent shortages, overfills, or spoilage, optimizing overall silo operations.

Infotech’s system is ideal for large industries due to its scalability, real-time monitoring capabilities, and IoT-driven automation, ensuring efficient management of multiple silos and large inventories.