Imagine a factory where machines talk to each other, predict their own maintenance needs, and optimise production without human intervention. Welcome to the world of Industrial IoT! The Industrial Internet of Things (IIoT) is reshaping manufacturing processes globally, and Qatar is no exception. With the help of Infotech Qatar, Industrial IoT in Qatar is rapidly advancing, bringing about significant changes in smart factory automation. This blog By Infotech Qatar explores the crucial role of Industrial IoT in Qatar’s smart factories, highlighting its benefits and applications.

What is Industrial IoT?

The Industrial Internet of Things (IIoT) integrates internet-connected devices in industrial applications. These devices collect, monitor, and analyse data to improve manufacturing processes’ efficiency, productivity, and safety. The IIoT enables real-time decision-making and predictive maintenance, leading to reduced downtime and optimized resource management.

How Industrial IoT Enhances Smart Manufacturing

Enhanced Efficiency and Productivity

Industrial IoT in Qatar results in innovative factory technology to control operations. Factories operate with sensors, machines, and data analytics to be more quickly efficient for production purposes.

- Proactivity: IoT sensors monitor your machinery; if they are about to fail or require attention, this information is delivered in real time.

- Predictive Maintenance: By taking all the data from IoT sensors and analysing it, it helps to predict when a piece of equipment requires maintenance so that there won’t be any unexpected breakdown, resulting in reduced maintenance costs.

- Automated Process: IIoT allows smart factory automation in which hands-on processes are eliminated, increasing the operation speed & accuracy.

Improved Quality Control

Quality Control is Improved, thanks to IIoT systems that closely check the production processes 24×7. This data can be analysed and used to verify in various stages of production that there is no defect, which will improve the quality of the product.

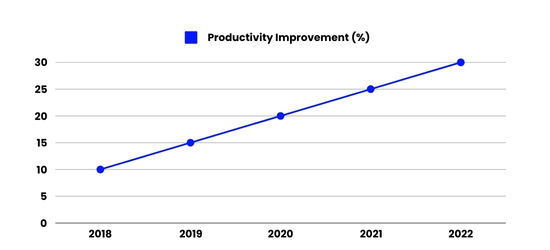

Productivity Improvement (Graph)

The Role of Smart Factory Solutions

Smart factory solutions are integral to the implementation of Industrial IoT. These solutions provide the infrastructure and tools necessary to create interconnected systems within a factory.

- Interconnected Systems: Smart factory technology connects machines, sensors, and software to enable seamless communication and data exchange.

- Data Analytics: Advanced analytics tools process large volumes of data to provide actionable insights, helping manufacturers make informed decisions.

- Scalability: Smart factory solutions are scalable, allowing manufacturers to expand their operations without significant disruptions.

The Future of Industrial IoT in Qatar

As the demand for advanced manufacturing solutions grows, the adoption of Industrial IoT in Qatar is expected to rise. Future trends include:

- Increased Automation: More factories will implement smart factory automation to stay competitive.

- AI Integration: Artificial Intelligence (AI) will be increasingly integrated with IoT systems to enhance predictive maintenance and decision-making.

- Sustainability: IIoT will make manufacturing processes more sustainable by optimising resource use and reducing waste.

Conclusion

The Industrial Internet of Things is revolutionising smart factory automation in Qatar, offering numerous benefits such as increased efficiency, improved quality control, and enhanced productivity. As more manufacturers adopt smart factory solutions, the future of industrial IoT in Qatar looks promising, with continued advancements and integration of new technologies. By leveraging the power of IIoT, Qatar’s manufacturing sector can achieve greater competitiveness and sustainability in the global market.

Frequently Asked Questions related to Industrial IoT

Which is an example of the Industrial Internet of Things?

An example of the Industrial Internet of Things (IIoT) is using predictive maintenance systems in manufacturing. These systems use sensors and data analytics to predict equipment failures before they occur, reducing downtime and maintenance costs.

What are the benefits of IIoT?

The benefits of IIoT include increased operational efficiency, improved product quality, enhanced safety, and reduced costs. IIoT enables real-time monitoring, predictive maintenance, and data-driven decision-making, leading to more streamlined and effective industrial operations.

How does IoT work in the industry?

In the industry, IoT works by integrating sensors and devices that collect data from machinery and processes. This data is transmitted to a central system, which is analysed and used to optimise operations, predict maintenance needs, and improve overall efficiency and safety.

What is the smart factory industrial Internet of Things?

The smart factory IIoT refers to integrating IoT technologies in manufacturing to create interconnected systems that improve automation, efficiency, and flexibility.

How can businesses implement Industrial IoT in Qatar?

Businesses in Qatar can implement IIoT by partnering with technology providers like Infotech Qatar, deploying IoT-enabled devices, integrating these with existing systems, and training staff for continuous system optimization.

Enhance your factory’s efficiency and productivity with cutting-edge IoT technology. Reach out to Infotech Qatar for a consultation on implementing Industrial IoT.